+1(909)-996-3687

Become A Dealer

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

AMB-L

ENERPAT

ENERPAT AMB-L1612-160 Ferrous Baler with Tipper

ENERPAT’s AMB-L series defines industry standards for durability and innovation. The unique Cover-Type Design provides unmatched structural integrity for handling the toughest, bulkiest scrap metal, setting it apart from conventional open-chamber balers.

This versatility makes the AMB-L1612-160 Ferrous Baler with Tipper an essential investment across multiple sectors:

Scrap Recycling Yards & Mega-Shredders: For operations drowning in loose metal, this baler is the key to survival and growth. It transforms scattered piles into shippable commodity bales, slashing costs and boosting profit margins instantly.

Foundries & Steel Mills: Achieve consistent, high-quality feedstock. Dense bales reduce melt time (by up to 30%), lower energy consumption (by over 20%), and minimize oxidation loss, leading to a cleaner melt and higher yield.

Large-Scale Manufacturing & Fabrication Plants: For automotive, aerospace, or machining shops generating tons of turnings and clippings. This baler enables on-site resource recovery, turning waste into a tidy revenue stream while enhancing workplace safety and supporting ESG goals.

Specialty Demolition & Dismantlers: For companies processing end-of-life vehicles (ELVs), industrial machinery, or white goods. The powerful cover-door mechanism crushes and condenses entire car shells, appliance bodies, and other challenging, high-volume items with ease.

Answering Your Critical Questions:

We understand your concerns about investment, suitability, and support. The AMB-L1612-160 is built to deliver a rapid Return on Investment (ROI)—often within 12-18 months—through tangible savings and increased scrap revenue. Its design prioritizes reliability and easy maintenance, using globally-recognized components to minimize downtime. Coupled with ENERPAT’s responsive global service network and available IoT monitoring options, we ensure your operation runs smoothly, maximizing your uptime and peace of mind.

Operating Principle

Material Feeding:

Materials are transported to the metal baler's compression chamber using forklifts and unloading devices.

Hydraulic Compression:

Under the drive of the hydraulic system, waste metal is compressed into compact metal bundles.

Automatic Bundle Ejection:

The metal bundles are automatically pushed out through a small door using a hydraulic cylinder.

Product Specification Sheet

| Model | AMB-L1480-160 | AMB-L2014-250 | AMB-L2520-315 |

| Press Force | 160 T | 250 T | 315 T |

| Press Chamber | 1400x800x700 mm | 2000x1400x900 mm | 2500x2000x1200 mm |

| Motor Power | 22 kw | 2x22 kw-6 | 2x45 kw-4 |

| Pump | 160 m/r | 2x160 m/r | 2x250 m/r |

| Bale Size | 350x350 mm | 500x500 mm | 500x500 mm |

| Capacity (Steel) | 2.0-2.5 tons per hour | 5.0 tons per hour | 8.0-10.0 tons per hou |

Why This Baler is a Non-Negotiable Investment for Your Industry

In today's competitive market, efficiency is currency. Simply collecting scrap is no longer enough. You must optimize its handling to protect your margins. This Ferrous Baler with Tipper is not an expense; it's a strategic profit center.

For Recyclers: It converts logistical overhead (storage, freight) into pure profit. The ability to produce premium bales makes you a preferred supplier to mills.

For Foundries: It standardizes your feedstock, giving you precise control over melt chemistry and efficiency, directly reducing your cost-per-ton of liquid metal.

For Manufacturers: It closes the loop on production waste, contributing to sustainability targets, reducing liability from scrap piles, and creating a new income source.

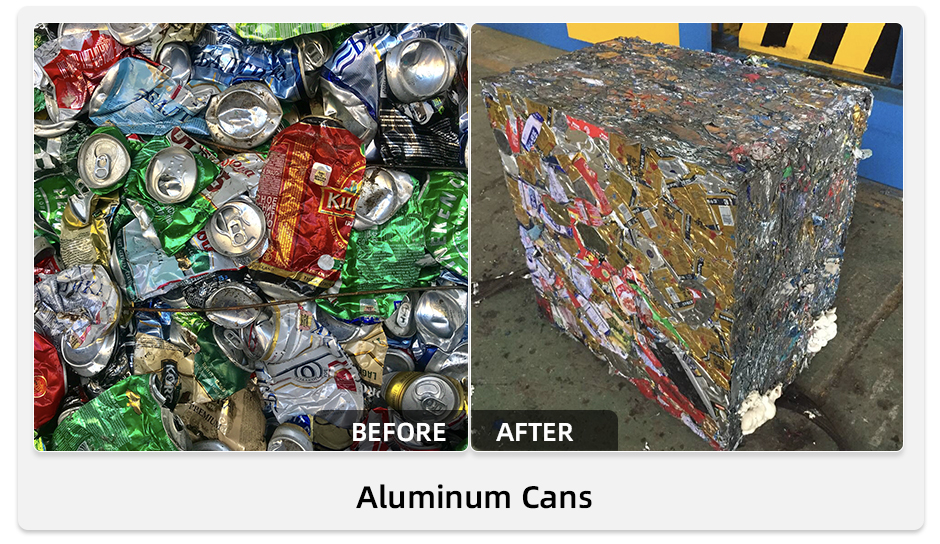

Material Testing

Ready to Transform Your Scrap Processing Efficiency?

Stop letting valuable space and profit vanish with loose scrap metal. Contact our engineering sales team today for a detailed quotation, a customized ROI analysis for your business, and to see the AMB-L1612-160 Ferrous Baler with Tipper in action through our video portfolio.

Get Your Personalized Quote Now

The ENERPAT AMB-L Series is a versatile scrap metal baler, also known as a scrap metal compactor, metal scrap baling machine, or metal recycling baler. It features a cleverly designed lid that enhances stability and durability. Utilizing hydraulic principles, it cold-presses materials into high-density metal bundles without the need for adhesives, preserving the metallic properties. The main oil cylinder compression force ranges from 100 to 1500 tons, and the motor power spans from 30 to 300 kW, accommodating the diverse needs of various customers.