+1(909)-996-3687

Become A Dealer

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

AMB-L

ENERPAT

Why Choose the ENERPAT Sheet Metal Baler?

ENERPAT's AMB-L series sets the standard in metal baling technology. Its unique door-cover design ensures stable compression and extended service life, while the advanced hydraulic system enables fast cycling and reliable performance. Whether you’re a scrap processor, manufacturer, or auto dismantler, this baler adapts to your needs – delivering consistent, mill-ready bales that meet international recycling standards.

Wide Industry Application:

Scrap Recycling Yards – process light iron, sheet metal, and mixed scrap efficiently.

Manufacturing Plants – handle stamping scrap, press shop leftovers, and production offcuts.

Automotive Dismantlers – compress car body panels, thin gauges, and mixed auto scrap.

Stainless Steel & Aluminum Fabricators – bale short runs, trimmings, and sheet offcuts.

Appliance Recycling Centers – compact washing machine shells, refrigerator panels, and home appliance scrap.

Operating Principle

Material Feeding:

Materials are transported to the metal baler's compression chamber using forklifts and unloading devices.

Hydraulic Compression:

Under the drive of the hydraulic system, waste metal is compressed into compact metal bundles.

Automatic Bundle Ejection:

The metal bundles are automatically pushed out through a small door using a hydraulic cylinder.

Product Specification Sheet

| Model | AMB-L1480-160 | AMB-L2014-250 | AMB-L2520-315 |

| Press Force | 160 T | 250 T | 315 T |

| Press Chamber | 1400x800x700 mm | 2000x1400x900 mm | 2500x2000x1200 mm |

| Motor Power | 22 kw | 2x22 kw-6 | 2x45 kw-4 |

| Pump | 160 m/r | 2x160 m/r | 2x250 m/r |

| Bale Size | 350x350 mm | 500x500 mm | 500x500 mm |

| Capacity (Steel) | 2.0-2.5 tons per hour | 5.0 tons per hour | 8.0-10.0 tons per hou |

Why Your Business Needs This Sheet Metal Baler

Investing in a door-cover baler is no longer optional – it's essential for staying competitive:

Slash Logistics Costs – Turn 3 truckloads of loose scrap into 1 compact load.

Maximize Storage – Reduce scrap footprint by 60–80% with stackable bales.

Increase Scrap Value – Produce dense, uniform bales that mills prefer and pay more for.

Improve Site Safety – Eliminate hazardous loose wires, sharp edges, and disorganized piles.

Streamline Operations – Standardize handling with forklift-friendly bales.

Support Sustainability Goals – Enhance ESG ratings and comply with environmental regulations.

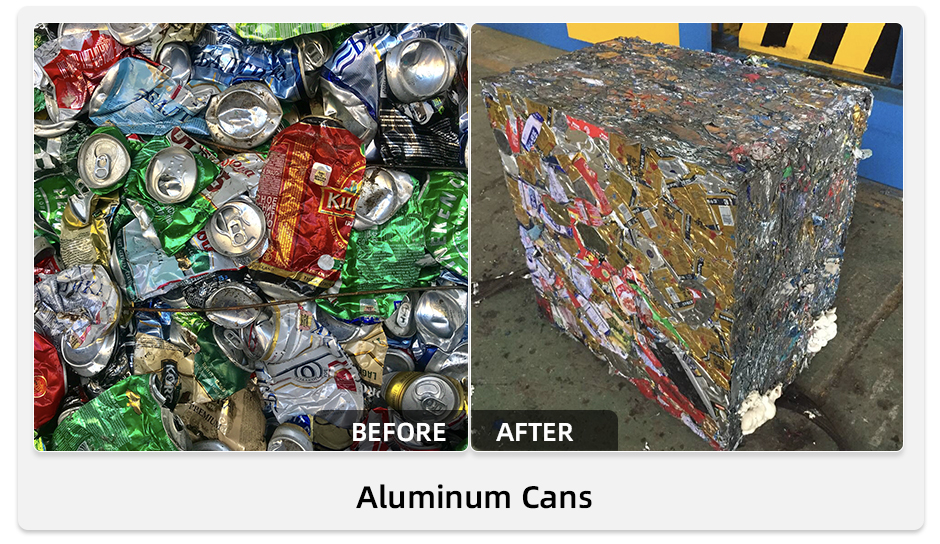

Material Testing

Ready to Transform Your Scrap Processing?

The ENERPAT AMB-L2014-250 Sheet Metal Baler is the reliable, high-performance solution for modern metal recycling. From cutting costs to boosting revenue – this machine delivers tangible ROI.

Contact us today for a customized quote, material test report, or site consultation. Let us help you build a smarter, more profitable scrap management system.

[Contact ENERPAT for Your Personalized Quote]

The ENERPAT AMB-L Series is a versatile scrap metal baler, also known as a scrap metal compactor, metal scrap baling machine, or metal recycling baler. It features a cleverly designed lid that enhances stability and durability. Utilizing hydraulic principles, it cold-presses materials into high-density metal bundles without the need for adhesives, preserving the metallic properties. The main oil cylinder compression force ranges from 100 to 1500 tons, and the motor power spans from 30 to 300 kW, accommodating the diverse needs of various customers.