+1(909)-996-3687

Become A Dealer

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

AMB-L

ENERPAT

ENERPAT AMB-L2017-250 High Density Wire Baler Machine

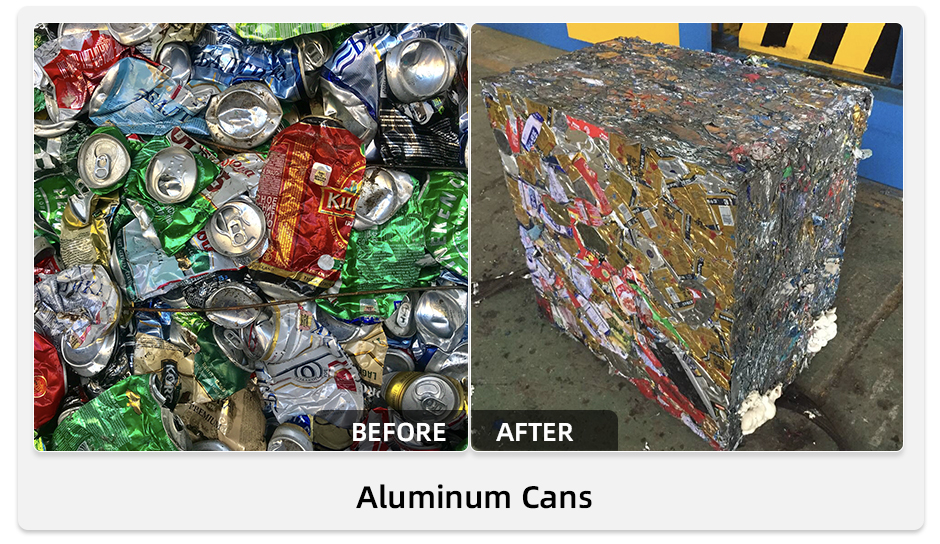

The ENERPAT AMB-L2017-250 High Density Wire Baler Machine is a robust hydraulic solution designed to tackle the most challenging scrap materials. Its unique door-cover design applies immense, focused pressure to compress loose, voluminous scrap into neat, stackable bales, drastically reducing storage space and transportation costs.

Materials It Processes:

This versatile baler is ideal for compressing large, bulky, stringy, and springy metals, including:

Light-Gauge Ferrous Scrap: Light Steel/Iron Scrap, Sheet Metal, Tinplate, White Goods (Appliance Shells, Washing Machine/Refrigerator Panels).

Manufacturing Offcuts: Stamping Scrap, Punching Scrap, Press Shop Scrap, Automotive Panel Scrap.

Non-Ferrous & Special Scrap: Stainless Steel (SS, SUS304/316) Offcuts, Aluminum Sheet/Profile Scrap.

Wire & Stringy Materials: Steel Wire Scrap, Spring Wire, Wire Brushing Scrap—perfect for creating the high-density wire bales this machine is named for.

Operating Principle

Material Feeding:

Materials are transported to the metal baler's compression chamber using forklifts and unloading devices.

Hydraulic Compression:

Under the drive of the hydraulic system, waste metal is compressed into compact metal bundles.

Automatic Bundle Ejection:

The metal bundles are automatically pushed out through a small door using a hydraulic cylinder.

Product Specification Sheet

| Model | AMB-L1480-160 | AMB-L2014-250 | AMB-L2520-315 |

| Press Force | 160 T | 250 T | 315 T |

| Press Chamber | 1400x800x700 mm | 2000x1400x900 mm | 2500x2000x1200 mm |

| Motor Power | 22 kw | 2x22 kw-6 | 2x45 kw-4 |

| Pump | 160 m/r | 2x160 m/r | 2x250 m/r |

| Bale Size | 350x350 mm | 500x500 mm | 500x500 mm |

| Capacity (Steel) | 2.0-2.5 tons per hour | 5.0 tons per hour | 8.0-10.0 tons per hou |

Designed for a Broad Spectrum of Clients:

Scrap Recycling Yards & Processors: Handle mixed light iron and wire scrap in volume. Produce dense, mill-grade bales to command higher prices and optimize logistics.

Manufacturing & Fabrication Plants: (Automotive, Appliance, Metalworking) Efficiently manage continuous streams of stamping offcuts, sheet trimmings, and production scrap, reclaiming valuable floor space.

Auto Dismantlers: Compress car body panels and mixed light auto sheet into compact, saleable bundles.

Specialty Metal Processors: (Stainless Steel, Aluminum) Bundle offcuts and short materials for tidy storage and improved recycling value.

Material Testing

Why This Machine is a Must-Have Investment

Slash Logistics Costs: Increase trailer/container loading efficiency by 3-6x, directly cutting high overseas freight expenses.

Reclaim Storage Space: Reduce scrap footprint by 60-80% through stackable baling.

Boost Revenue: Mills consistently pay premium prices for "dense, baled scrap" compared to loose, bulky material.

Enhance Site Safety: Eliminate hazards from scattered, sharp-edged sheets and tangled wires.

Standardize Operations: Create uniform, easy-to-handle blocks that streamline material handling with forklifts and cranes.

Ready to Transform Your Scrap Operations?

The ENERPAT AMB-L2017-250 High Density Wire Baler Machine is more than just equipment; it's a strategic investment in operational efficiency, safety, and profitability.

Contact us today for a detailed quotation, technical datasheet, or to discuss your specific application needs. Let our experts help you build a smarter, more profitable scrap management system.

The ENERPAT AMB-L Series is a versatile scrap metal baler, also known as a scrap metal compactor, metal scrap baling machine, or metal recycling baler. It features a cleverly designed lid that enhances stability and durability. Utilizing hydraulic principles, it cold-presses materials into high-density metal bundles without the need for adhesives, preserving the metallic properties. The main oil cylinder compression force ranges from 100 to 1500 tons, and the motor power spans from 30 to 300 kW, accommodating the diverse needs of various customers.