+1(909)-996-3687

Become A Dealer

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

AMB-L

ENERPAT

Why Choose the ENERPAT AMB-L Series?

ENERPAT is a globally recognized brand with a proven track record of delivering durable and efficient recycling equipment. The AMB-L series is deployed worldwide, serving a diverse range of industries that require reliable scrap preprocessing.

Who Needs This Metal Scrap Baler & Why It's Essential

Scrapyards & Metal Recyclers: Increase the value and marketability of your scrap. Dense, uniform bales command better prices from mills and reduce shipping costs significantly by optimizing trailer and container load capacity.

Metal Mills & Foundries: Ensure consistent furnace feed. Uniform bale density and size lead to more predictable melt chemistry, improved energy efficiency in Electric Arc Furnaces (EAFs), and reduced metal loss.

Auto Dismantlers & ELV Processors: Efficiently handle car bodies, panels, and residual frames. Baling reduces storage space, minimizes safety hazards from loose sharp metal, and prepares material for streamlined logistics.

Manufacturing & Stamping Plants: Manage in-house production scrap like sheet offcuts, turnings, and wire. Baling simplifies on-site handling, improves housekeeping, and prepares scrap for direct sale or internal recycling.

Demolition & Large-Scale Contractors: Process mixed metals from construction sites. Baling transforms unwieldy piles of beams, conduits, and miscellaneous metal into tidy, transportable packages.

Investing in a closed-door scrap baler for sale is not just about compaction; it's a strategic business decision driven by logistics economics, metallurgical efficiency, and adherence to international trading standards like the ISRI Scrap Specifications.

Operating Principle

Material Feeding:

Materials are transported to the metal baler's compression chamber using forklifts and unloading devices.

Hydraulic Compression:

Under the drive of the hydraulic system, waste metal is compressed into compact metal bundles.

Automatic Bundle Ejection:

The metal bundles are automatically pushed out through a small door using a hydraulic cylinder.

Product Specification Sheet

| Model | AMB-L1480-160 | AMB-L2014-250 | AMB-L2520-315 |

| Press Force | 160 T | 250 T | 315 T |

| Press Chamber | 1400x800x700 mm | 2000x1400x900 mm | 2500x2000x1200 mm |

| Motor Power | 22 kw | 2x22 kw-6 | 2x45 kw-4 |

| Pump | 160 m/r | 2x160 m/r | 2x250 m/r |

| Bale Size | 350x350 mm | 500x500 mm | 500x500 mm |

| Capacity (Steel) | 2.0-2.5 tons per hour | 5.0 tons per hour | 8.0-10.0 tons per hou |

Material Testing

Get Your Customized Quote Today!

Ready to transform your scrap metal handling and boost your bottom line? The ENERPAT AMB-L2520-250 metal scrap baler for sale is a proven solution for serious processors.

Contact us now for a detailed quotation, site-specific configuration advice, and to arrange a live demonstration. Let our experts help you find the perfect baler for your needs.

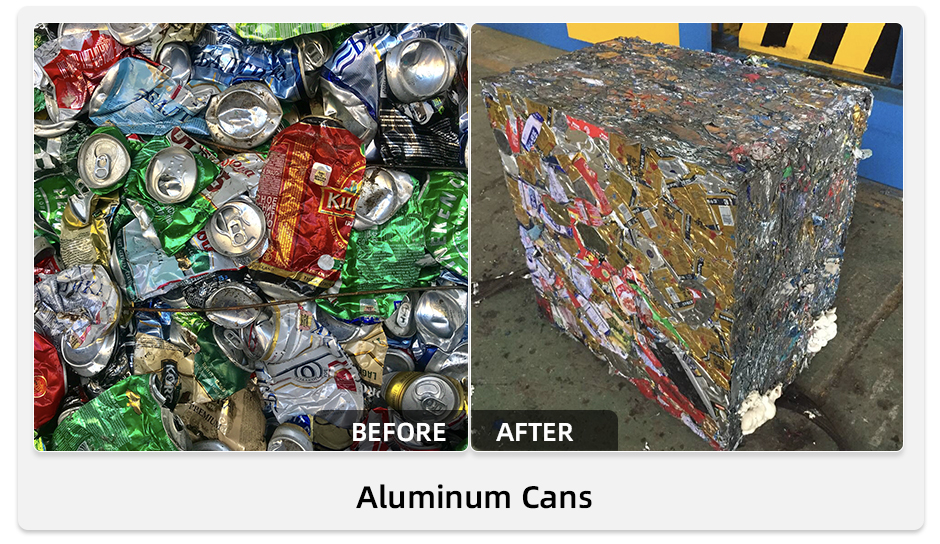

The ENERPAT AMB-L Series is a versatile scrap metal baler, also known as a scrap metal compactor, metal scrap baling machine, or metal recycling baler. It features a cleverly designed lid that enhances stability and durability. Utilizing hydraulic principles, it cold-presses materials into high-density metal bundles without the need for adhesives, preserving the metallic properties. The main oil cylinder compression force ranges from 100 to 1500 tons, and the motor power spans from 30 to 300 kW, accommodating the diverse needs of various customers.