+1(909)-996-3687

Become A Dealer

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

AMB-L

ENERPAT

A High-Performance Baler for Diverse Scrap

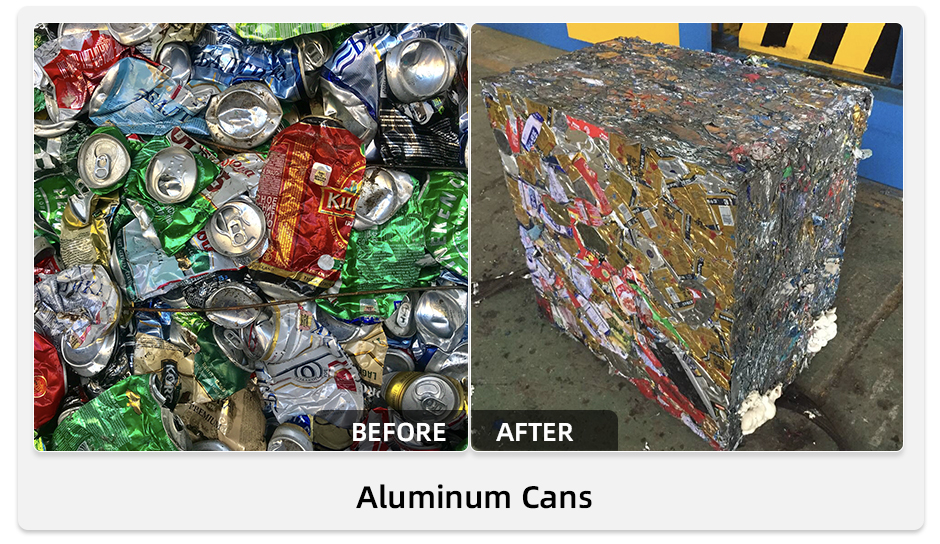

The ENERPAT AMB-L1480-160 is a robust door-type scrap metal baler, part of our renowned AMB-L series. It specializes in compressing a wide range of scrap metals—from high-value non-ferrous materials like aluminium wire, bright copper (#1 Copper), and aluminum turnings (swarf) to bulky ferrous scrap such as steel scrap, rebar, and automotive shells. Its unique door-cover design delivers immense force to handle large, irregular, and hard-to-compress materials with ease.

The AMB-L1480-160 Scrap Metal Baler Machine for Aluminium Wire operates on a simple, efficient three-step principle: loading, compression, and automatic bale ejection. For enhanced workflow efficiency, an optional Tipper (Automatic Feeding Hopper) can be integrated, allowing for quicker and easier loading of bulk materials, further reducing labor and cycle times.

Why Choose ENERPAT?

As a leader in recycling equipment, ENERPAT combines decades of engineering expertise with global component sourcing. Our balers, proven in demanding markets like North America and Europe, are built for longevity and reliability. The versatility of the AMB-L1480-160 makes it the ideal choice not just for specialized aluminium wire processors, but for a broad spectrum of clients:

Scrap Metal Recyclers & Yards: Turn piles of loose scrap into profitable, transportable bales.

Foundries & Smelters: Achieve faster melt times, lower energy consumption, and more consistent charge material.

Manufacturing Plants: (e.g., automotive, aluminum extrusion) Manage production scrap like turnings and cuttings on-site, improving housekeeping and creating a new revenue stream.

Specialized Recyclers: (e.g., ELV, WEEE, battery recycling) Handle tough, irregular items like car bodies or battery casings effectively.

Operating Principle

Material Feeding:

Materials are transported to the metal baler's compression chamber using forklifts and unloading devices.

Hydraulic Compression:

Under the drive of the hydraulic system, waste metal is compressed into compact metal bundles.

Automatic Bundle Ejection:

The metal bundles are automatically pushed out through a small door using a hydraulic cylinder.

Product Specification Sheet

| Model | AMB-L1480-160 | AMB-L2014-250 | AMB-L2520-315 |

| Press Force | 160 T | 250 T | 315 T |

| Press Chamber | 1400x800x700 mm | 2000x1400x900 mm | 2500x2000x1200 mm |

| Motor Power | 22 kw | 2x22 kw-6 | 2x45 kw-4 |

| Pump | 160 m/r | 2x160 m/r | 2x250 m/r |

| Bale Size | 350x350 mm | 500x500 mm | 500x500 mm |

| Capacity (Steel) | 2.0-2.5 tons per hour | 5.0 tons per hour | 8.0-10.0 tons per hou |

Why Your Industry Must Invest in This Scrap Metal Baler Machine for Aluminium Wire

Investing in the ENERPAT baler is a strategic upgrade, not just a purchase. It is essential for:

Cost Competitiveness: Directly cuts your two largest costs—storage and logistics.

Revenue Enhancement: Dense bales command premium prices from buyers.

Operational Excellence: Enables cleaner, safer, and more efficient yard or plant management.

Sustainability Goals: Transforms waste into a tidy, efficient resource, boosting your ESG credentials.

Market Expansion: Allows you to accept and profitably process a wider, more challenging variety of scrap materials.

Material Testing

Get Your Customized Quote Today!

Ready to transform your metal scrap processing and boost your bottom line? The ENERPAT AMB-L1480-160 Scrap Metal Baler Machine for Aluminium Wire is your proven solution.

Contact us now for a detailed quotation, a personalized ROI analysis, or to arrange a live demonstration. Let our experts help you configure the perfect baler for your specific needs.

The ENERPAT AMB-L Series is a versatile scrap metal baler, also known as a scrap metal compactor, metal scrap baling machine, or metal recycling baler. It features a cleverly designed lid that enhances stability and durability. Utilizing hydraulic principles, it cold-presses materials into high-density metal bundles without the need for adhesives, preserving the metallic properties. The main oil cylinder compression force ranges from 100 to 1500 tons, and the motor power spans from 30 to 300 kW, accommodating the diverse needs of various customers.