+1(909)-996-3687

Become A Dealer

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

AMB-L

ENERPAT

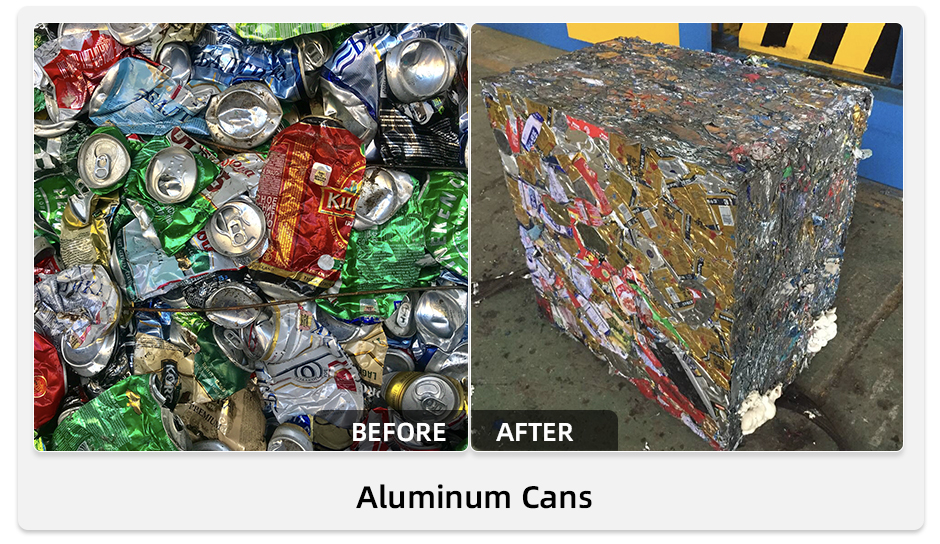

Materials It Can Process

This versatile scrap metal baler is designed to handle a comprehensive range of recyclable metals. Ideal for baling:

Light Steel Scrap: Light gauge scrap, tinplate, iron sheet, shear cut scrap.

Production Offcuts: Stamping scrap, punching scrap, metal machining offcuts, sheet metal offcuts.

Non-Ferrous Scrap: Aluminum sheet scrap, aluminum profile/ extrusion scrap, brass and copper sheet scrap (loose & thin).

Stainless Steel Scrap: Stainless steel offcuts, SUS304/316 scrap.

Auto Dismantling Scrap: Car body panels, doors, hoods, fenders, auto body sheet scrap.

Appliance & E-Waste Scrap: Washing machine shells, refrigerator (metal casing), appliance housing scrap.

Operating Principle

Material Feeding:

Materials are transported to the metal baler's compression chamber using forklifts and unloading devices.

Hydraulic Compression:

Under the drive of the hydraulic system, waste metal is compressed into compact metal bundles.

Automatic Bundle Ejection:

The metal bundles are automatically pushed out through a small door using a hydraulic cylinder.

Industry Applications & Why It's Essential

Our door-type scrap metal baler serves a wide spectrum of industries by solving core challenges related to volume, handling, and profitability.

Scrap Metal Recyclers & Yards: Essential for compressing mixed light scrap, loose collections, and fragmented metals. It dramatically increases bale density, leading to higher selling prices from mills and smelters while slashing transportation costs by 30-50%.

Auto Dismantling & ELV (End-of-Life Vehicle) Processors: Perfect for compacting car body shells, doors, and hoods after shredding. It reduces storage space by up to 90%, making yard management efficient and preparing clean, dense bales for the furnace.

Metal Manufacturing & Fabrication: A must-have for aluminum extrusion plants, stainless steel workshops, sheet metal fabricators, and stamping factories. It continuously processes production offcuts, shear scrap, and trimmings on-site, keeping work areas clean and turning waste into a compact, revenue-generating commodity.

E-Waste & Appliance Recycling Centers: Effectively crushes and bales the bulky metal housings from white goods like refrigerators, washers, and ovens, improving line efficiency and material handling.

Scrap Exporters & Port-Side Operations: For traders, achieving maximum container load density is critical. This baler produces consistently sized, high-weight bales that optimize shipping space and boost export profitability.

Why is this door-type scrap metal baler a necessary investment for these industries? Unlike standard horizontal balers, the unique door-lid design provides a powerful secondary compression action specifically engineered for low-density, high-volume metallic scrap. It achieves superior bale density where other machines struggle, directly translating to lower storage footprint, reduced hauling frequency, and enhanced scrap value—delivering a rapid return on investment.

Product Specification Sheet

| Model | AMB-L1480-160 | AMB-L2014-250 | AMB-L2520-315 |

| Press Force | 160 T | 250 T | 315 T |

| Press Chamber | 1400x800x700 mm | 2000x1400x900 mm | 2500x2000x1200 mm |

| Motor Power | 22 kw | 2x22 kw-6 | 2x45 kw-4 |

| Pump | 160 m/r | 2x160 m/r | 2x250 m/r |

| Bale Size | 350x350 mm | 500x500 mm | 500x500 mm |

| Capacity (Steel) | 2.0-2.5 tons per hour | 5.0 tons per hour | 8.0-10.0 tons per hou |

Material Testing

Get Your Custom Quote Today

Ready to transform your metal scrap handling and boost your profitability? Contact our engineering team today for a detailed quotation and application-specific consultation.

The ENERPAT AMB-L Series is a versatile scrap metal baler, also known as a scrap metal compactor, metal scrap baling machine, or metal recycling baler. It features a cleverly designed lid that enhances stability and durability. Utilizing hydraulic principles, it cold-presses materials into high-density metal bundles without the need for adhesives, preserving the metallic properties. The main oil cylinder compression force ranges from 100 to 1500 tons, and the motor power spans from 30 to 300 kW, accommodating the diverse needs of various customers.

![]()

Hastir Joachim

"Since introducing the ENERPAT lid-type scrap metal baler, our production efficiency has significantly improved. The machine operates stably with a low failure rate, greatly saving maintenance time and costs. The lid design makes operation more convenient, and the quality of the bales is uniform, making it ideal for our recycling industry needs. The after-sales service is prompt, and the team is professional; overall, we are very satisfied!"

![]()

Menzi Gama

"The ENERPAT lid-type scrap metal compactor performs exceptionally well at our large solid waste disposal center. The machine has strong processing capabilities, efficiently handling large volumes of solid waste materials and significantly improving our work efficiency. The intelligent control system is simple to use, allowing employees to quickly get up to speed and reducing training costs. Additionally, the durability and stability of the equipment ensure worry-free long-term operation, making it the preferred choice in the field of solid waste management!"