+1(909)-996-3687

Become A Dealer

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2026-01-28 Origin: Site

In the heart of Morocco’s growing agricultural and industrial sector, efficiency is no longer a luxury—it is a survival requirement. Recently, ENERPAT successfully commissioned a high-performance Wood Shaving Production Line with Bagging System for a prominent farm owner and import-export entrepreneur in Morocco.

This case study explores how integrated automation solved a critical supply chain bottleneck for premium animal bedding.

The Challenge: Bridging the Gap in Horse Bedding Supplies

Our Moroccan client manages a diverse portfolio, including farm operations and food product logistics. His primary pain point was the urgent need for high-quality wood shavings for horse stables. With a target output of 1 ton per hour and a specific requirement for 15-20kg bags, manual processing was out of the question.

The client faced high labor costs, inconsistent shaving quality, and the logistical nightmare of transporting loose material. He needed a "turnkey" solution that could transform raw logs into market-ready, compressed bags with minimal human intervention. After a targeted search for a reliable Wood Shaving Production Line with Bagging System, he partnered with ENERPAT.

The Solution: A Seamless, Fully Automated Line

To meet the 1t/h capacity and the strict bagging requirements, ENERPAT engineered a customized wood shaving and bagging equipment solution. The line integrates shaving, drying, and precision weighing into one continuous flow.

Core Equipment Technical Specifications

1. ENERPAT EWS-30 Wood Shaving Machine Designed for heavy-duty wood processing, this Wood Shavings Machine sets the industry standard for durability and adjustable shaving thickness.

|

|

2. ENERPAT HBA-B60 Bagging Press Machine This high-degree automation Bagging Press Machine utilizes dual hydraulic cylinders to compress loose shavings into uniform, easy-to-stack bags.

|

|

Morocco's Market Outlook: Why Now is the Time to Invest

The Moroccan wood processing landscape is undergoing a massive shift. For investors currently on the fence, the data suggests a significant "first-mover" advantage:

The Supply Gap: Recent data indicates that Morocco's domestic wood production only meets 31% of national demand. This creates a massive opportunity for local businesses to process wood waste into value-added products like animal bedding and biomass.

Market Scale: The Moroccan market for wood chips and residues reached approximately 5 million cubic meters in 2022, with a total value of nearly $499M USD.

Policy Support: As of 2025, the Moroccan government has implemented protective tariffs on imported wood products to bolster local manufacturing. Under the "Forests of Morocco 2020–2030" strategy, there is a clear roadmap for improved forest management and resource utilization.

Renewable Energy Trend: With Morocco's aggressive push toward renewable energy, the demand for compressed wood waste (shavings and sawdust) as a carbon-neutral fuel source is projected to climb.

Customer Success: From Waste to Profit

By implementing the ENERPAT Wood Shavings Line, the client successfully bypassed the volatility of the import market. The integrated sawdust bagging machine and weighing system reduced his labor requirements by 60%, while the compact 15-20kg bales significantly lowered his transportation costs per unit.

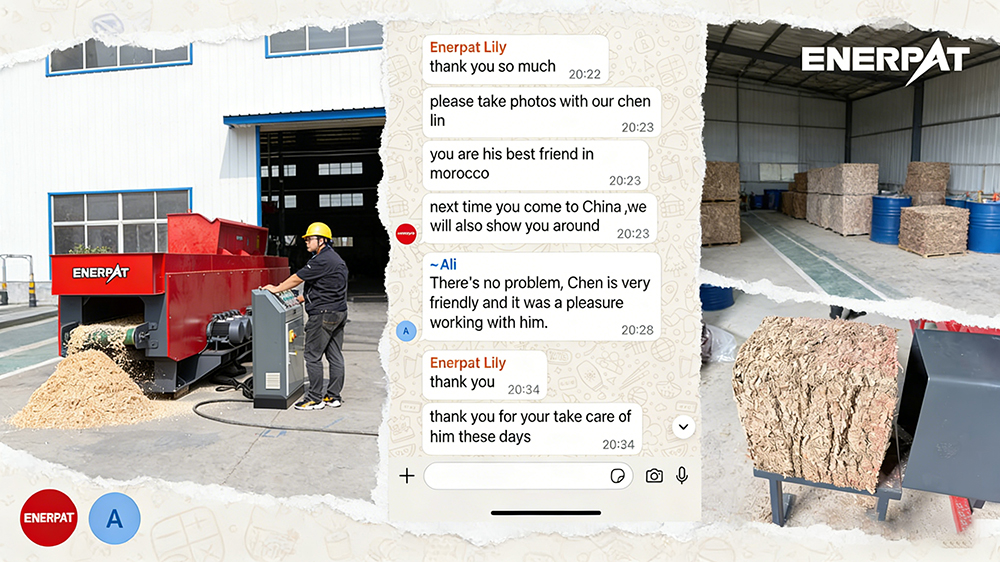

Today, this facility serves as an ENERPAT flagship site in Morocco. The client is so satisfied with the system’s performance and the rapid ROI that he welcomes prospective buyers to visit the site and see the Wood Shaving Production Line with Bagging System in full operation.

Why Choose ENERPAT?

As a global leader in recycling and processing technology, ENERPAT combines British engineering excellence with high-efficiency manufacturing. We don't just sell machines; we provide end-to-end solutions that include:

Customized Engineering: Tailoring production lines to your specific material and bag weight.

Global Components: Using Siemens, Schneider, and Hallite components for easy local maintenance.

Proven Track Record: Thousands of successful installations worldwide.

Ready to transform your wood waste into a profitable venture? Contact our expert team today for a customized quote and technical consultation. Let us help you build a more sustainable and profitable future.

Call us today! +1(909)-996-3687

Email: info@enerpatrecycling.com