+1(909)-996-3687

Become A Dealer

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

AMB-L

ENERPAT

ENERPAT Steel Scrap Baler with Door Cover

The ENERPAT Door Cover Type Steel Scrap Baler is an industrial-grade compression solution designed specifically for processing challenging metal waste streams. This robust steel scrap baler efficiently handles various difficult-to-compress materials, transforming them into compact, uniform bales that are ideal for transportation and recycling.

Why ENERPAT's Steel Scrap Baler Stands Out:

Superior Door Cover Design

Our unique door cover design ensures exceptional stability and durability during operation. The reinforced box welding structure with tenon-and-mortice connection provides unmatched structural integrity, allowing continuous operation even under heavy-duty conditions.

Powerful Hydraulic System

Experience efficient baling with our advanced hydraulic system that defines new standards in performance:

Cartridge valve block with large flow capacity and fast operation

H-type tapered connections that prevent oil leakage

British Hallite brand cylinder seals for safety and durability

Industrial Cooling System

Our built-in industrial cooling system maintains optimal operating temperatures 24/7. Choose between "fixed temperature" or "room temperature synchronization" modes to support continuous operation across multiple shifts.

Intelligent Control System

The Siemens/Schneider PLC control system offers:

Touchscreen/button operation for simplicity

Automatic alarm programs for easy maintenance

Smart programming for customizable compression and feeding times

Real-time monitoring of operation time, current, and temperature

Operating Principle

Material Feeding:

Materials are transported to the metal baler's compression chamber using forklifts and unloading devices.

Hydraulic Compression:

Under the drive of the hydraulic system, waste metal is compressed into compact metal bundles.

Automatic Bundle Ejection:

The metal bundles are automatically pushed out through a small door using a hydraulic cylinder.

Product Specification Sheet

| Model | AMB-L1480-160 | AMB-L2014-250 | AMB-L2520-315 |

| Press Force | 160 T | 250 T | 315 T |

| Press Chamber | 1400x800x700 mm | 2000x1400x900 mm | 2500x2000x1200 mm |

| Motor Power | 22 kw | 2x22 kw-6 | 2x45 kw-4 |

| Pump | 160 m/r | 2x160 m/r | 2x250 m/r |

| Bale Size | 350x350 mm | 500x500 mm | 500x500 mm |

| Capacity (Steel) | 2.0-2.5 tons per hour | 5.0 tons per hour | 8.0-10.0 tons per hou |

Material Testing

Industry Applications

Various industries generate metal waste that our steel scrap baler can efficiently process:

Construction & Demolition: Rebar, steel beams, channels, and angles from building sites

Manufacturing & Metalworking: Stamping scraps, punching scraps, and machining byproducts

Automotive Sector: End-of-life car bodies, wheels, and manufacturing offcuts

Household Appliance Production: Steel scraps from manufacturing and obsolete appliances

Recycling Facilities: Mixed steel scraps of various shapes and sizes

Customer Case Studies

North American Recycling Industry Customization

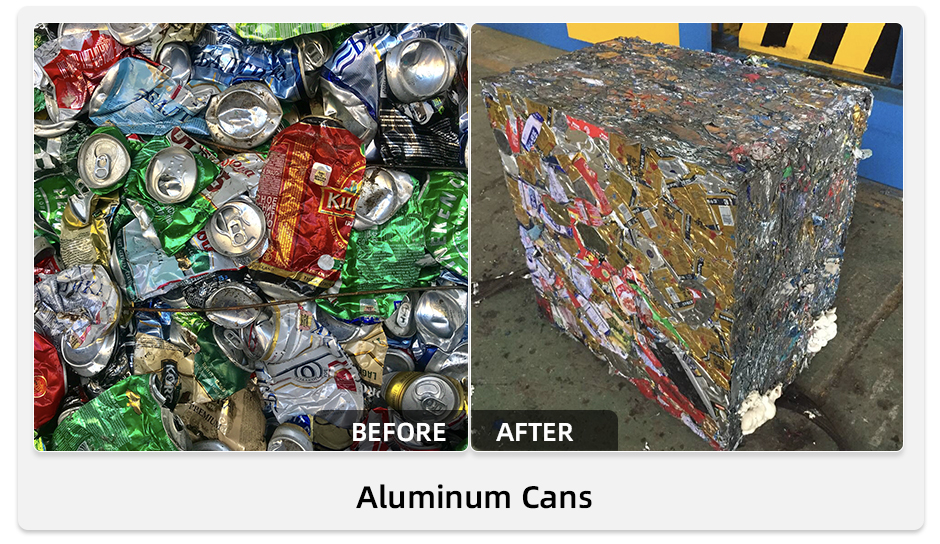

Materials Processed: Beverage cans, scrap iron

Processing Capacity: 8 tons/hour

North American Furniture Industry Spring Baler

Materials Processed: Various springs

Processing Capacity: 6 tons/hour

Suzhou Auto Parts Company Aluminum Chips Processing

Materials Processed: Filamentous aluminum chips

Processing Capacity: 2 tons/hour

Ready to transform your metal waste management? Contact us today for a personalized consultation and discover how our ENERPAT Door Cover Type Steel Scrap Baler can optimize your operations and boost your profitability.

The ENERPAT AMB-L Series is a versatile scrap metal baler, also known as a scrap metal compactor, metal scrap baling machine, or metal recycling baler. It features a cleverly designed lid that enhances stability and durability. Utilizing hydraulic principles, it cold-presses materials into high-density metal bundles without the need for adhesives, preserving the metallic properties. The main oil cylinder compression force ranges from 100 to 1500 tons, and the motor power spans from 30 to 300 kW, accommodating the diverse needs of various customers.

![]()

Hastir Joachim

"Since introducing the ENERPAT lid-type scrap metal baler, our production efficiency has significantly improved. The machine operates stably with a low failure rate, greatly saving maintenance time and costs. The lid design makes operation more convenient, and the quality of the bales is uniform, making it ideal for our recycling industry needs. The after-sales service is prompt, and the team is professional; overall, we are very satisfied!"

![]()

Menzi Gama

"The ENERPAT lid-type scrap metal compactor performs exceptionally well at our large solid waste disposal center. The machine has strong processing capabilities, efficiently handling large volumes of solid waste materials and significantly improving our work efficiency. The intelligent control system is simple to use, allowing employees to quickly get up to speed and reducing training costs. Additionally, the durability and stability of the equipment ensure worry-free long-term operation, making it the preferred choice in the field of solid waste management!"