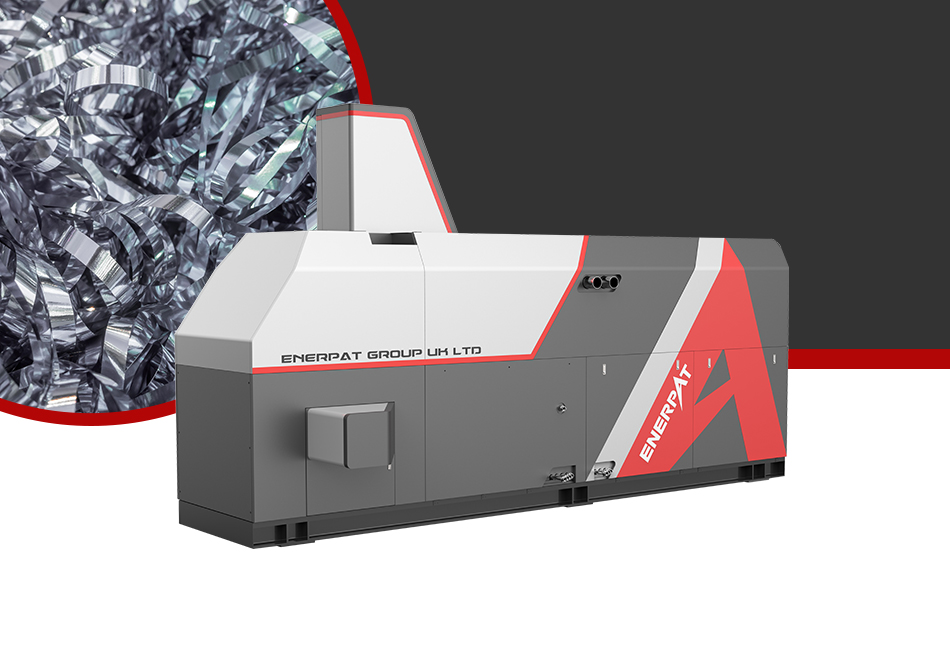

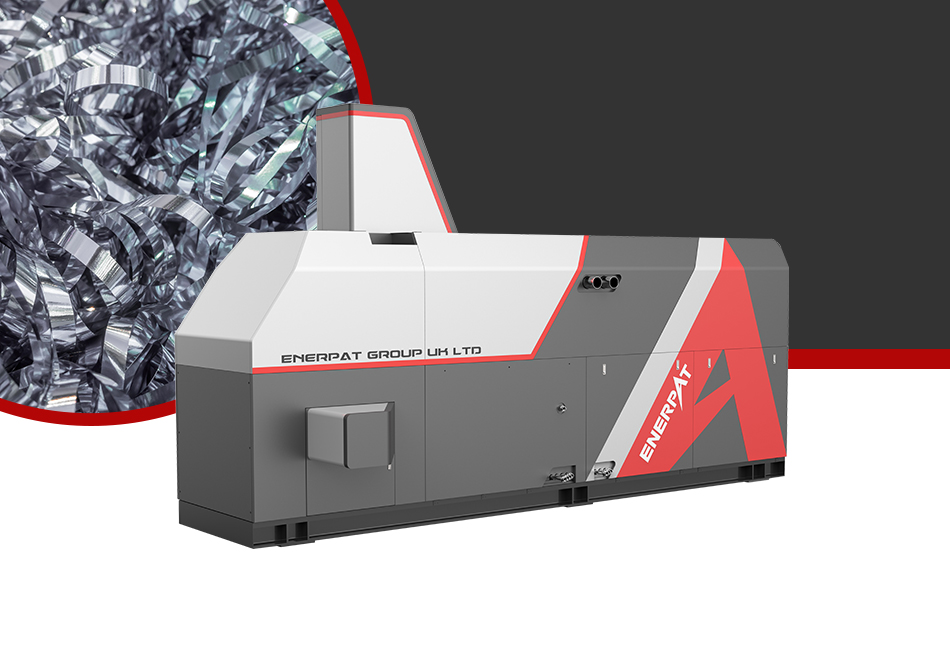

When James, a production manager at a metal fabrication company, reviewed the monthly waste reports, he was stunned by the volume of metal chips and shavings piling up from their machining processes. Not only were these metal scraps taking up valuable space, but they also represented a significant l

Read More

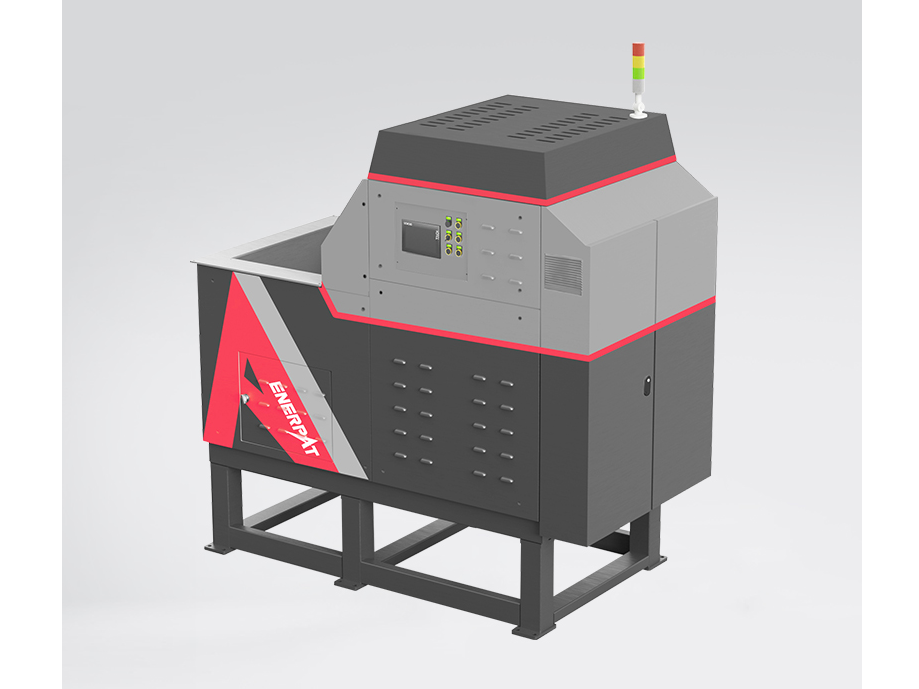

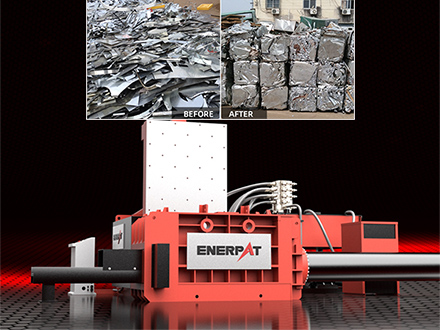

In the realm of recycling, aluminum is one of the most valuable materials due to its endless recyclability and widespread application. Aluminum briquette machines transform scrap aluminum into compact, dense blocks, streamlining the recycling process and increasing both efficiency and profitability

Read More

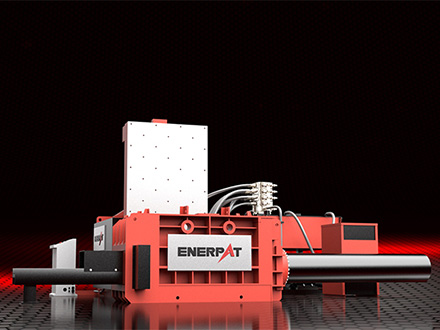

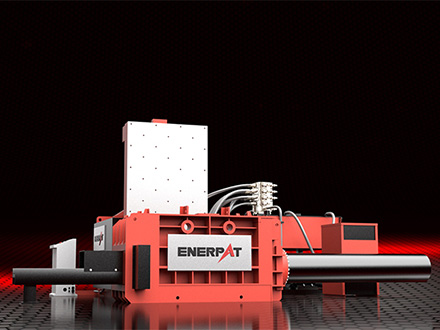

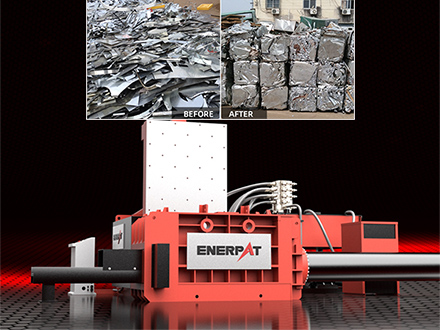

In February 2025, a major Australian mattress recycler reached out to ENERPAT via enerpatbalers.com, seeking a scrap metal baling machine for sale capable of processing dense, resilient mattress springs. Their inquiry, "We recycle mattresses and need a baler that can handle mattress springs. Please

Read More

When John, the operations manager of a mid-sized metal fabrication company, noticed the increasing piles of metal chips and shavings accumulating in his facility, he realized it was time to find an efficient solution. The waste not only consumed valuable space but also represented a loss of potentia

Read More

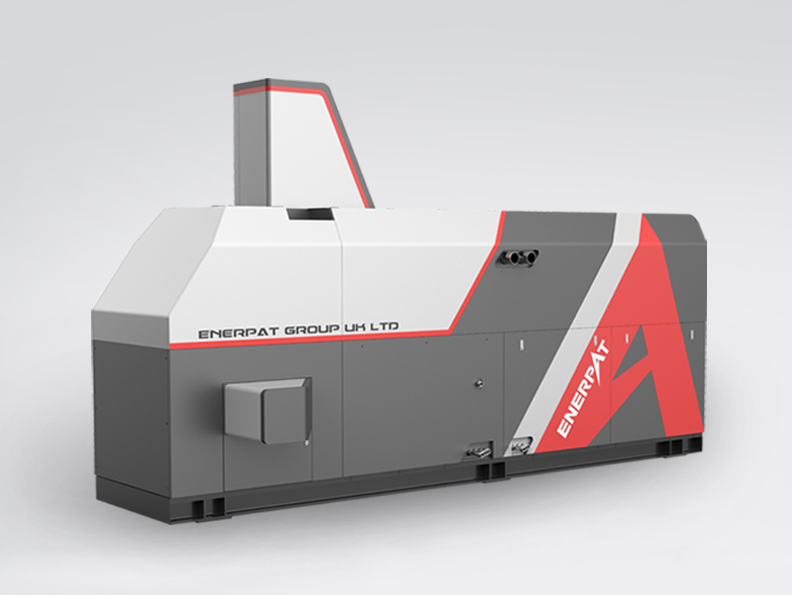

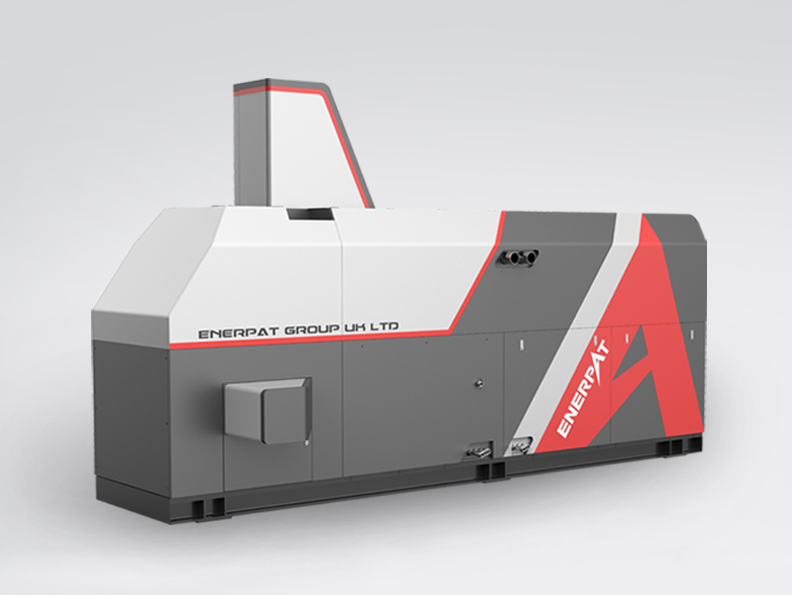

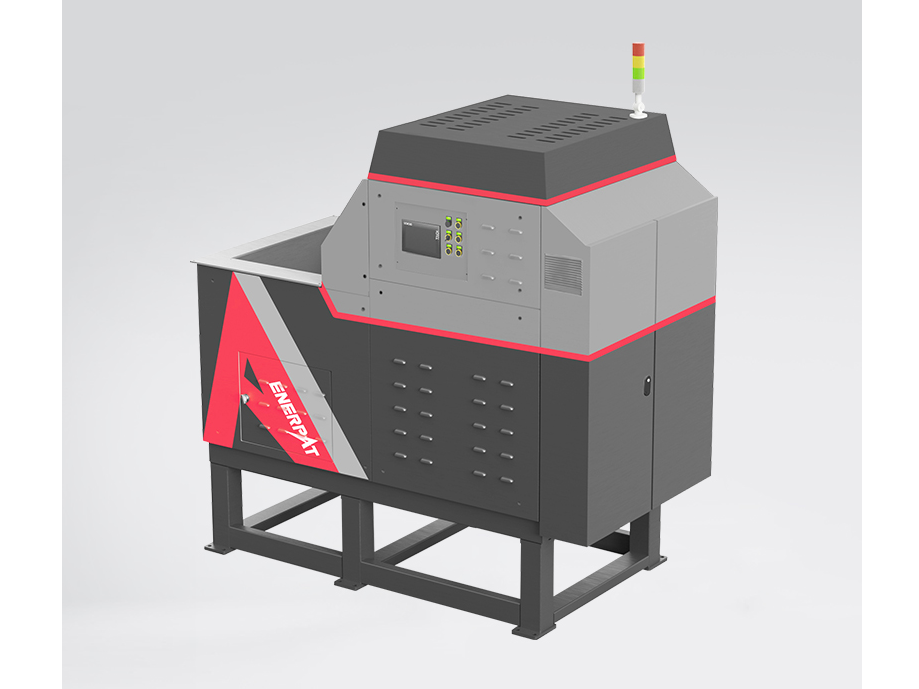

IntroductionIn modern industrial manufacturing environments, managing waste materials effectively is critical not only for environmental sustainability but also for workplace safety and operational cleanliness. One of the most efficient and cost-effective methods to achieve these goals is Metal Chip

Read More

Introduction: A Recycler’s Search for a High-Capacity Non Ferrous BalerIn February 2025, a U.S.-based metal recycler faced a critical bottleneck: their aging non ferrous baler (18.6kW, 203mm cylinder) struggled to compact mixed copper, brass, and aluminum shims into dense, uniform bales. Operating w

Read More

Client Background and ChallengesA leading UK metalworking manufacturer specializing in aerospace-grade titanium alloy components faces significant issues handling large volumes of titanium swarf generated during precision machining:l Waste accumulation: Loose titanium swarf occupies valuable worksho

Read More

Client Background & Challenges An Australian metal manufacturer specializing in stainless steel, aluminum, copper, and mixed metals faced two key issues:l Returned Goods Risk: Preventing resale by completely destroying returned products.l Inefficient Scrap Processing: High costs and space usage with

Read More