+1(909)-996-3687

Become A Dealer

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-19 Origin: Site

As industries across the globe seek more efficient and sustainable waste management solutions, compacting technology plays an essential role. A trash compactor, typically used for general waste disposal, and a Metal Chip Compactor, a more specialized machine, serve similar yet distinct purposes. In this article, we'll explore the key differences between these two types of compactors, focusing on how a Metal Chip Compactor, like the ENERPAT BM Series, revolutionizes metal waste recycling. We'll also highlight its crucial role in reducing environmental impact and enhancing operational efficiency.

A trash compactor, often found in residential and commercial settings, is a machine designed to reduce the volume of waste by compressing it into a smaller, more manageable size. This compression helps save space and simplifies waste storage. The compacted waste can then be collected and disposed of more efficiently.

However, when it comes to industrial settings, particularly in metalworking and manufacturing industries, the need for more specialized machinery becomes clear. This is where the Metal Chip Compactor comes into play. Unlike a general trash compactor, which handles typical garbage, a Metal Chip Compactor is engineered to handle metal shavings, chips, and scrap materials generated during production processes.

A Metal Chip Compactor is specifically designed to handle the unique waste produced during metalworking. These machines work by compressing metal shavings or chips into solid briquettes, effectively reducing their volume. This process not only improves storage but also prepares the metal waste for recycling.

In addition to volume reduction, the Metal Chip Compactor also separates cutting fluids from the metal waste. These fluids, which are used in metalworking to lubricate and cool the cutting tools, are efficiently recovered, leading to a cleaner operation. For example, ENERPAT’s BM Series Metal Chip Compactor boasts an impressive 95% oil recovery rate, ensuring that the cutting oil can be recycled and reused, thus minimizing waste and reducing environmental pollution.

The importance of a Metal Chip Compactor in industries dealing with metalworking waste cannot be overstated. Industrial metal waste, such as iron, aluminum, copper, and stainless steel shavings, often occupies large amounts of space, and without proper compaction, it can lead to costly waste disposal processes. By compacting metal chips into solid briquettes, the compactor optimizes space utilization, making it easier to store and transport waste materials.

Moreover, these briquettes can often be sold at a higher price in the recycling market, contributing to significant cost savings. For instance, with a Metal Chip Compactor, businesses can increase their recycling prices by 2000-3000 RMB per ton of iron shavings. This helps businesses not only save money on waste management but also gain financial returns from selling the recycled metal.

The primary function of a Metal Chip Compactor is to compress metal waste into manageable briquettes, but there are several other key functions that enhance its utility in industrial applications:

Oil Recovery: One of the most crucial aspects of a Metal Chip Compactor is its ability to separate cutting fluids from metal chips during the compaction process. With an oil recovery rate of up to 95%, the compactor ensures that the precious cutting fluid is recovered for reuse, which lowers overall costs and minimizes the environmental impact of waste disposal.

Space Optimization: Metal waste, if left uncompressed, can take up a significant amount of space in factories. Compaction reduces the volume of the waste, allowing businesses to store more waste in a smaller area. This leads to better organization and makes the entire waste management process more efficient.

Improved Recycling Opportunities: The briquettes produced by a Metal Chip Compactor are uniform and dense, making them easier to transport, store, and sell to recyclers. This streamlined process can lead to higher recycling rates, which benefits both the environment and the business's bottom line.

The advantages of using a Metal Chip Compactor extend beyond the immediate operational benefits. These machines offer both environmental and economic gains for businesses in the manufacturing sector.

Environmental Benefits:

Reduction in Pollution: By recovering cutting fluids and reducing the volume of metal waste, Metal Chip Compactors help to mitigate the environmental impact of metalworking operations. The reduction in waste and pollution also ensures that businesses comply with environmental regulations and pass environmental inspections with ease.

Sustainability: The ability to recycle metal waste more effectively leads to a more sustainable manufacturing process. Rather than sending metal chips and shavings to landfills, businesses can recycle them, contributing to a circular economy.

Economic Benefits:

Cost Savings: Compaction of metal waste reduces disposal costs and can even turn waste into a revenue stream. By improving the density and uniformity of metal briquettes, manufacturers can secure higher recycling prices.

Efficient Waste Management: With space optimization and oil recovery, the operational costs of managing waste are significantly reduced. This leads to better resource allocation and reduced need for additional waste storage or transportation.

Long-Term Profitability: The ENERPAT BM Series Metal Chip Compactor, for example, pays for itself over time through savings on waste disposal and recycling revenue. The compacted waste can be sold at a higher price, which translates into a substantial return on investment.

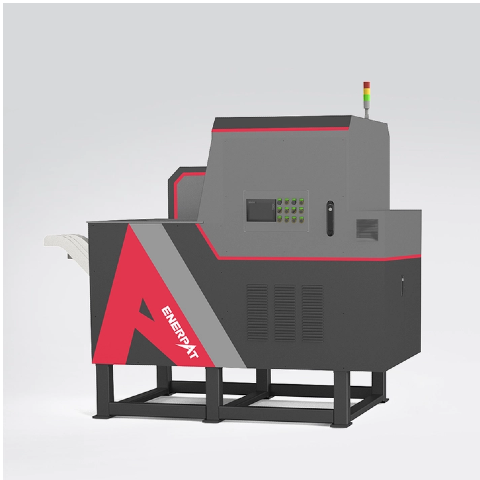

When it comes to reliable and efficient metal waste compaction, the ENERPAT BM Series Double Output Metal Chip Compactor stands out. This advanced machine can compress various types of metal waste, including iron, aluminum, stainless steel, and copper, into compact briquettes. It also separates cutting fluids with a high recovery rate, ensuring a clean operation with minimal waste.

The BM Series is widely used in industries such as automotive manufacturing and machinery production. Its robust construction and superior performance ensure that it can handle large volumes of metal waste, making it an ideal solution for businesses looking to optimize their waste management processes.

Metal Chip Compactors, like the ENERPAT BM Series, play a critical role in the modern industrial waste management landscape. By efficiently compacting metal chips, recovering valuable cutting fluids, and optimizing space utilization, these machines offer both environmental and economic benefits. They help businesses reduce waste, lower disposal costs, and even generate revenue through recycled materials.

For companies in metalworking industries, investing in a Metal Chip Compactor is an essential step towards improving sustainability and operational efficiency. The ENERPAT BM Series Metal Chip Compactor offers advanced technology and unmatched reliability, making it the ideal choice for businesses looking to enhance their waste management practices.

If you're ready to improve your waste management processes and boost your recycling efforts, contact us to learn more about the ENERPAT BM Series Metal Chip Compactor.