+1(909)-996-3687

Become A Dealer

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-08-17 Origin: Site

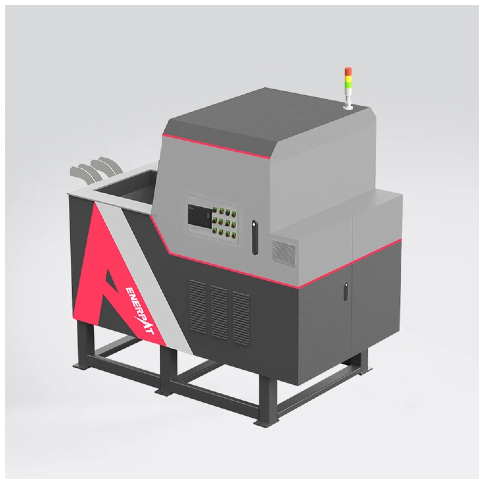

Efficient waste management is critical for businesses, especially those that generate large quantities of waste, such as metal shavings from manufacturing processes. Among the most effective tools for reducing waste volume and improving storage efficiency is the trash compactor. However, for industrial environments dealing with metal waste, a more specialized piece of equipment is required— the Metal Chip Compactor. This guide will focus on how to effectively use a metal chip compactor, particularly the ENERPAT BM Series Double Output Metal Chip Compactor, to optimize space, improve recycling, and streamline industrial waste management.

A trash compactor is a device that compresses waste materials to reduce their volume. This can be especially useful in industrial settings where managing large amounts of waste is essential. By compacting the waste, a trash compactor helps to minimize storage space, reduce handling costs, and make waste disposal more efficient.

In industrial applications, especially those involving metal manufacturing, waste such as metal shavings, scraps, and chips are generated in large quantities. Traditional trash compactors may not be equipped to handle this type of waste. That’s where a Metal Chip Compactor comes into play. The Metal Chip Compactor, like the ENERPAT BM Series, is specifically designed to handle metal chips, compressing them into solid briquettes that are easier to store, recycle, and transport.

Using a metal chip compactor in an industrial setting requires a few key steps to ensure optimal performance and maximum benefits. Here’s how to effectively use a metal chip compactor:

Before using the compactor, it’s essential to prepare the metal waste properly. Metal shavings often come mixed with oils and cutting fluids, which can interfere with the compaction process. For best results, separate these fluids from the metal waste before loading it into the compactor. The ENERPAT BM Series Metal Chip Compactor excels in this area, offering a high oil recovery rate of up to 95%. This feature helps separate the cutting fluids from the metal chips, ensuring cleaner and more efficient compaction.

Once the waste has been prepared, it is time to load it into the compactor. Even distribution is key when loading metal chips into the compactor’s hopper. This ensures that the compaction process is even, preventing clogs or uneven briquettes. The ENERPAT BM Series compactor is designed with user-friendly features to make the loading process quick and efficient.

Different types of metal waste may require different levels of compaction pressure. The ENERPAT BM Series provides powerful hydraulic force to handle tough metal chips, compressing them into solid briquettes. The machine is designed to adapt to various materials and adjust pressure accordingly for optimal compaction, which helps improve the efficiency of waste handling.

It’s important to keep an eye on the compaction process to ensure everything is running smoothly. The ENERPAT BM Series features advanced control systems that monitor the compaction process, making adjustments as needed. This results in consistent and uniform briquettes, improving the overall efficiency of metal waste processing.

Once the metal chips have been compressed into briquettes, they are easier to handle, store, and transport. The compressed briquettes also have a higher recycling value. Metal recycling facilities prefer briquettes over loose chips because they are easier to process. By using a metal chip compactor, businesses can significantly reduce their metal waste volume and increase the value of their recyclable materials.

Investing in a metal chip compactor offers numerous benefits, especially in industries dealing with large amounts of metal waste. Here are some key advantages:

One of the primary benefits of using a metal chip compactor is improved space efficiency. Loose metal shavings take up considerable space, which can lead to clutter and inefficiency in a facility. By compacting metal waste into solid briquettes, space is freed up for other operations, allowing for more streamlined workflow and better resource allocation.

The compacted briquettes are more valuable to recycling facilities. The higher density and uniformity of the briquettes make them easier to transport and process, which in turn increases their recycling value. With the ENERPAT BM Series Metal Chip Compactor, companies can increase their recycling revenue by up to 2000-3000 RMB per ton of metal waste, such as iron shavings.

Using a metal chip compactor is a highly effective way to promote environmental sustainability. By recovering oils and cutting fluids, the process minimizes waste and ensures that these valuable materials are properly recycled. The ENERPAT BM Series boasts a 95% oil recovery rate, which reduces the environmental impact of industrial waste and helps companies meet environmental regulations.

A metal chip compactor helps companies save on several fronts. By reducing waste volume, businesses can cut down on storage and transportation costs. Furthermore, the higher recycling value of the compacted metal chips translates into increased revenue, making the investment in a metal chip compactor a cost-effective solution for many industries.

Many industrial facilities must comply with environmental standards and regulations regarding waste management. The ENERPAT BM Series Metal Chip Compactor is CE and ISO certified, ensuring that it meets global environmental and safety standards. By using this compactor, businesses can stay compliant with regulations while improving their waste management practices.

Beyond the direct benefits of waste management, a metal chip compactor can significantly improve the overall efficiency of an industrial operation. By reducing the time spent on waste handling, companies can refocus resources on production, thus enhancing overall productivity. Moreover, the process of compacting metal waste makes it easier for manufacturers to segregate scrap metal for recycling, contributing to a more organized and efficient facility.

Additionally, when metal waste is processed into uniform briquettes, it becomes easier to transport to recycling facilities. Loose chips, on the other hand, can be messy and hard to handle, requiring additional labor and equipment for storage and transportation. The briquettes produced by the compactor are far more convenient to move and store, reducing labor costs and improving logistics efficiency.

Using a Metal Chip Compactor, such as the ENERPAT BM Series Double Output Metal Chip Compactor, can provide significant improvements in how industrial waste is handled, recycled, and disposed of. From reducing waste volume and optimizing space to increasing recycling value and promoting sustainability, the benefits are clear. By investing in a metal chip compactor, businesses can not only improve their waste management efficiency but also increase their profitability and environmental sustainability.

For more information on how the ENERPAT BM Series Metal Chip Compactor can benefit your operations, contact us today. Let ENERPAT’s expertise help you take your industrial waste management to the next level.